Vision AIFood & Beverage

ClearVision custom Vision AI solutions reduce risk and improve quality for Food & Beverage production through data-informed updates to operations. Capturing images from the production floor and analyzing that data with the latest in Artificial Intelligence, our inference engine provides actionable insights to drive continuous improvement.

Vision AI Solutions are customized and optimized to:

-

- Improve Code Date Label Efficiency

- Identify Foreign Matter in Food Processing & Packaging

- Monitor Consistency and Detect Blemishes

ClearVision at the Edge tracks the length of french fries in production before they are frozen and packaged to ensure product consistency.

Vision AI with ClearVision Benefits

Quality

Vision AI deployed at the edge provides real-time analysis to identify defects and eliminate false-positives, improving both quality and efficiency.

Efficiency

ClearVision reduces downtime and increases throughput with insights into operations. Lines run faster, longer, and with higher accuracy than those monitored by human eyes.

Profits

Reduce waste, cut labor costs, increase throughput, and minimze downtime so QA professionals can focus on solving quality concerns, not on monitoring the lines.

Safety

ClearVision Inference Engince will identify PPE violations, monitor hazardous work areas, and reduce emergency shutdowns to increase worker safety and keep operations running.

Connected

ClearVision integrates seamlessly into your existing systems, and can often use images from existing cameras.

ClearVision Food & Beverage Solution Examples

Vision AI from ClearObject is making Food & Beverage producers more efficient, safer, and more profitable with solutions designed for their unique environments. Confectioners, Meat & Poultry, Dairy, and other Food & Beverage sub-verticals are harvesting the benefits of insights from artificial intelligence.

If you can see it, we can automate it.

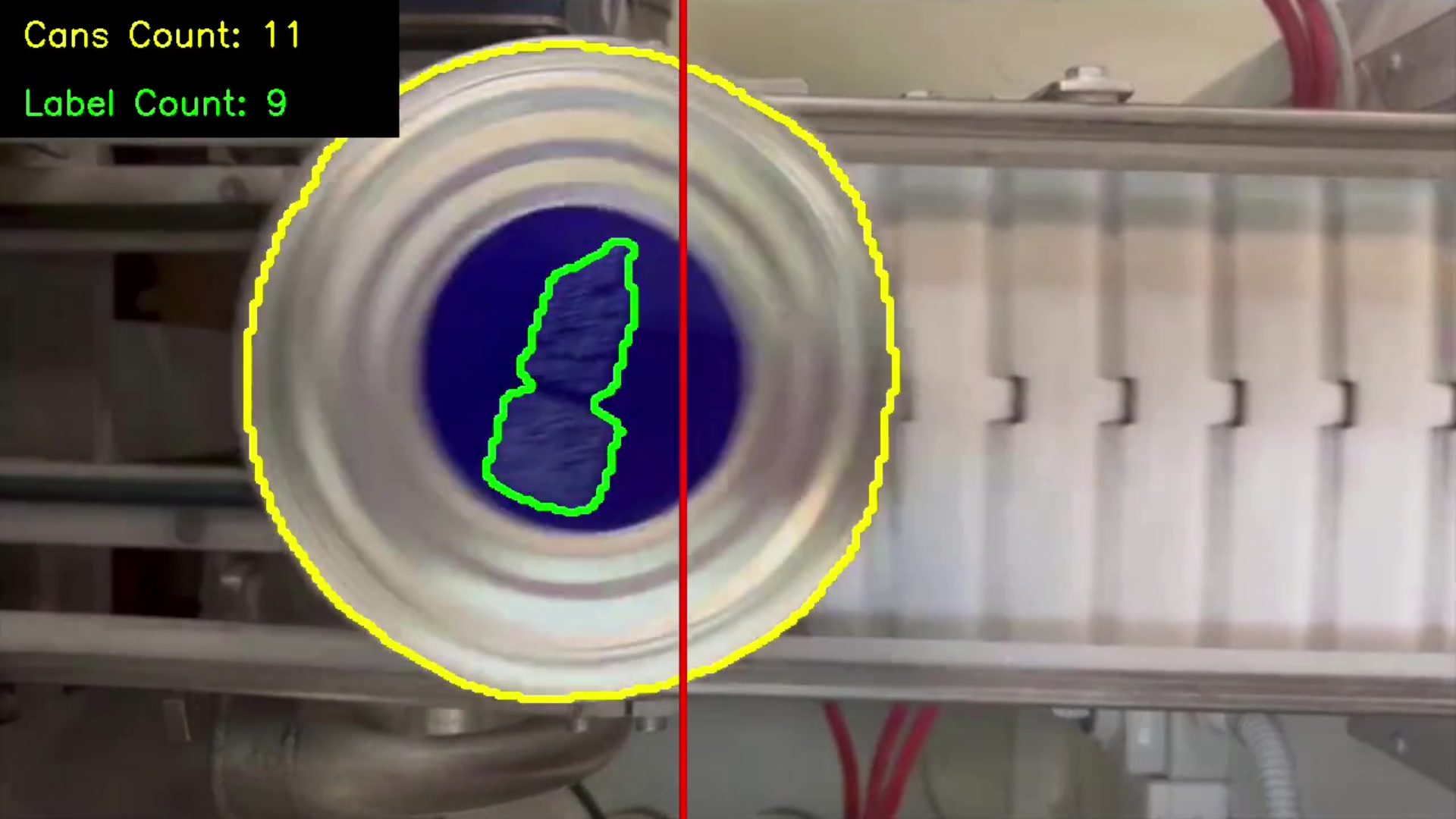

Vision AI identifies packages with missing labels in real time to minimize risk and improve compliance

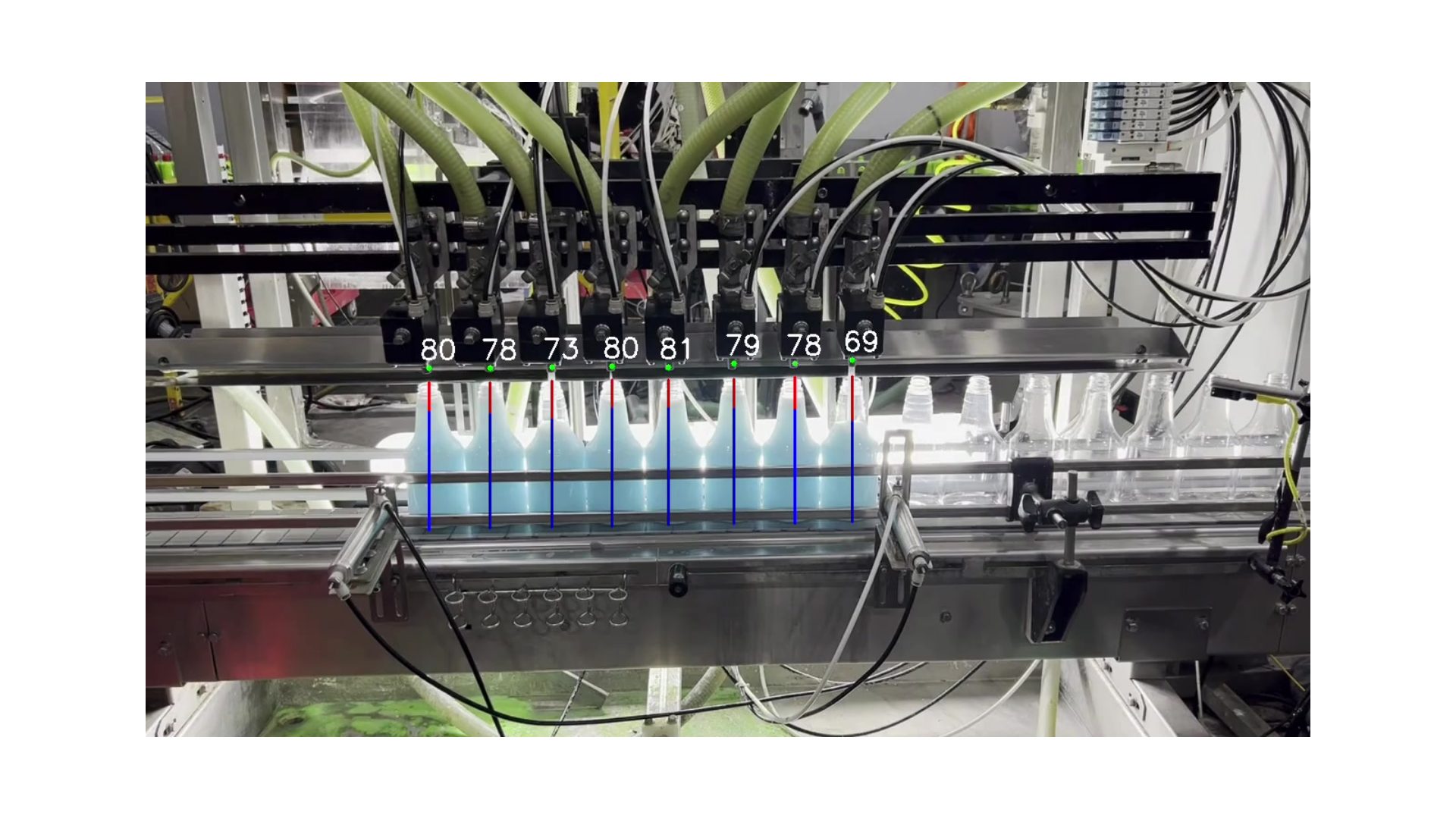

Fill volumes are monitored and communicated to the PLC to prevent underfilling and overfilling

Vision AI tracks the production counts of sweet pastries to optimize efficiency and reduce waste

Computer Vision AI counts items dropped into packaging while ensuring the desired SKU mix is achieved.

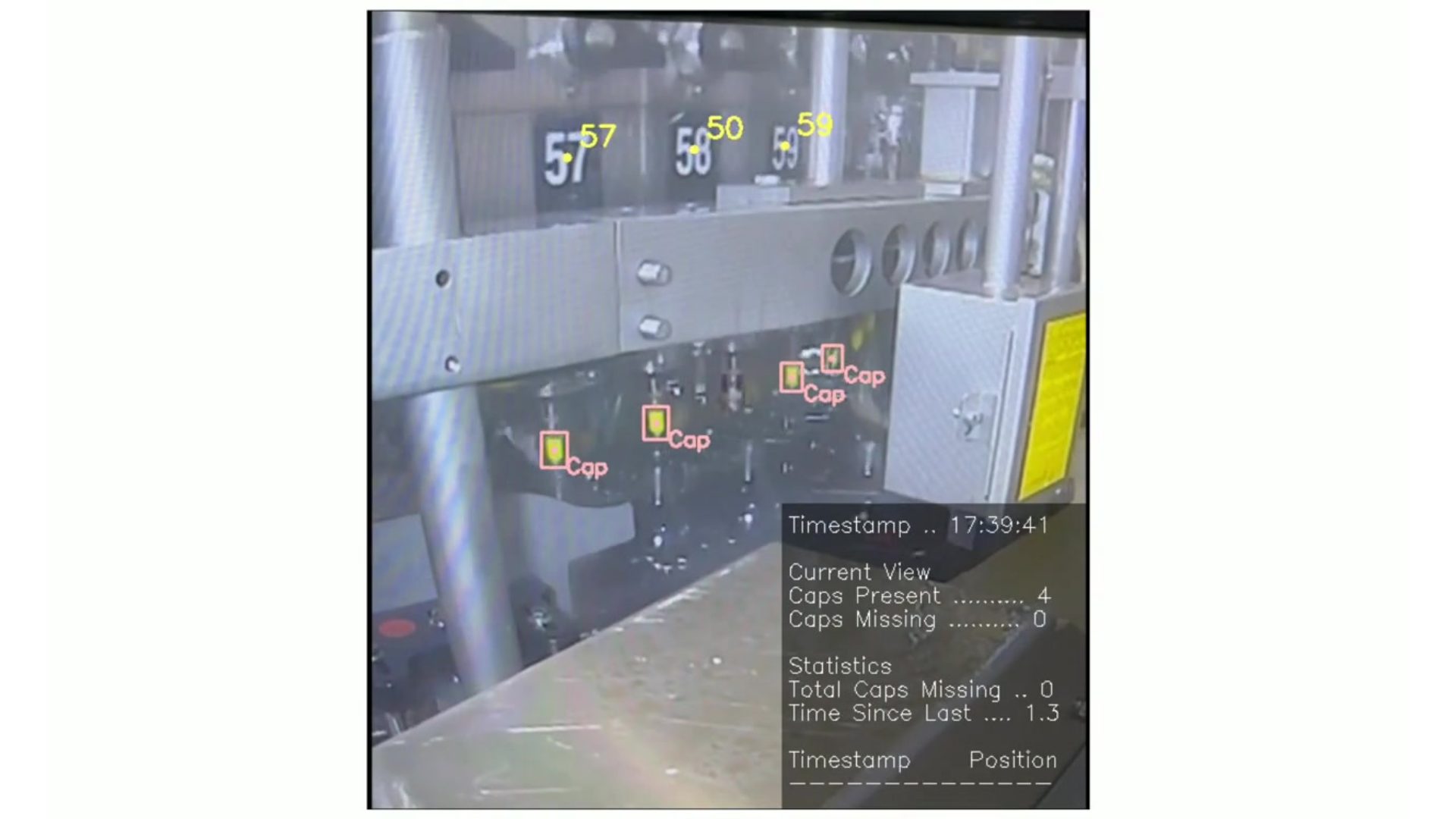

ClearVision Vision AI identifying missing or damaged vent tubes in a bottling facility.

Where do you need to improve performance?

- Quality Control

- Foreign Matter Detection

- Code Date Labeling

- Equipment Efficiency

Webinar On-Demand

Food Date Label Monitoring with Vision AI

The Food Labeling Act of 2023 is poised to reshape the way products are labeled and usher in a new era of transparency and accountability. ClearObject Vision AI solutions can be installed on your existing lines to identify if the code date label is missing, misplaced, hard to read, or if the printer is running low on ink. Learn about food labeling along with the Food Traceability Act and new SEC rules for reporting on emissions, and how Vision AI can help.

How It Works

Vision AI from ClearObject helps our customers solve complex problems efficiently, accurately and cost-effectively. Using existing cameras, or installing food-safe cameras and housings, ClearVision turns images into structured data, offering actionable insights into how to solve the challenges facing your business.

Capture

Record data from existing or new cameras and sensors optimized for your business requirements and operating environments.

Curate

To make sense of the captured data, Data Scientists build customized categories based on your specific use cases.

Label

ClearObject best practices, including working with customer SMEs, ensure the highest quality annotations are used to create the most accurate models possible.

Validate

Data Scientists will partner with customer SMEs to confirm that all categories and data labeling are accurate and aligned with business needs.

Train

Once accuracy is confirmed, our experts will design and train a highly customized AI model for your specific use case.

Deploy

Launch the new AI model and train staff on how to interpret the visualized dashboard of operational data.

Iterate

Continually iterate on the AI model to adjust for new learnings, optimizations, and changing business requirements.