Vision AI for Food & Beverage

Safer Products, Happier CustomersVision AI improves quality control and food safety

Reduce downtime and improve quality with real-time Vision AI insights into Food & Beverage production

Safer Products, Happier CustomersVision AI improves quality control and food safety

Reduce downtime and improve quality with real-time Vision AI insights into Food & Beverage production

Why Vision AI for Food & Beverage Production?

Vision AI uses artificial intelligence techniques to interpret and understand visual information from images or videos. If you can see it and understand it, a Vision AI solution can do the same, more quickly and consistently to drive margins by improving efficiencies and reducing waste.

Vision AI for Food & Beverage Use Cases

Quality Control

Monitor product count, shape, color and volume while collecting data for root cause analysis and future improvements

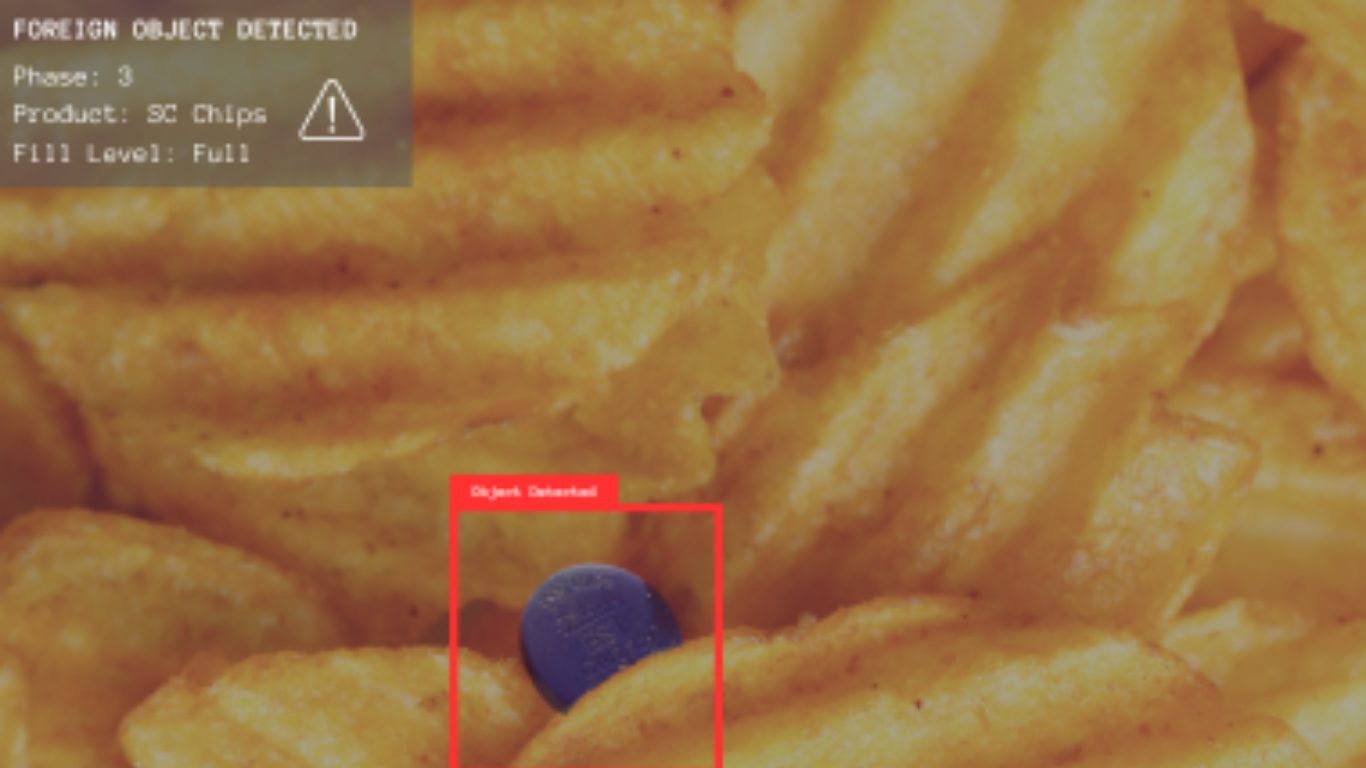

Foreign Object Detection

Identify dangerous foreign material on the line or in free fall to improve product consistency and avoid costly recalls

Worker Safety

Confirm workers are wearing the correct PPE and are in safe work locations with real time alerts to deviations

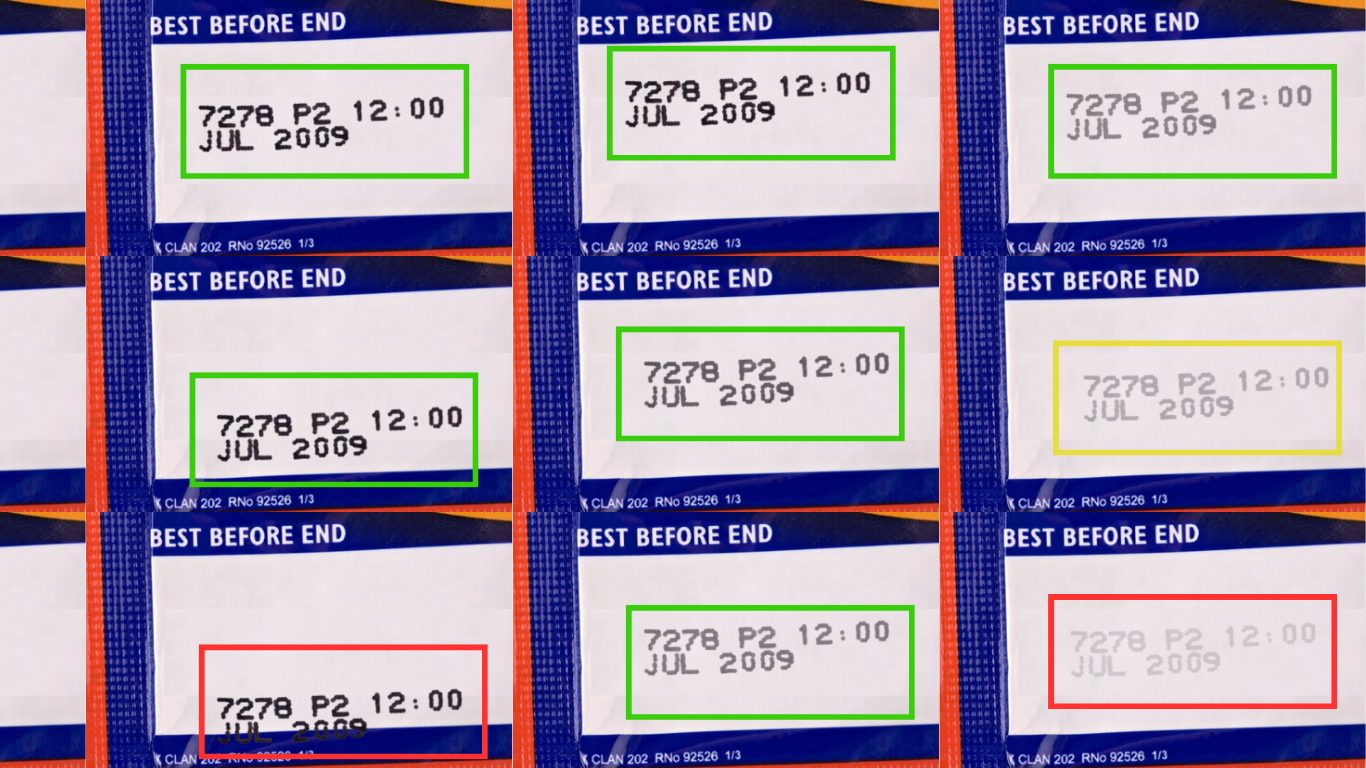

Code Date Label Verification

Vision AI confirms labels are accurate, legible, and placed properly to meet retailer and distributor requirements

Waste Reduction

Increase efficiency and reduce waste with highly accurate process monitoring and portioning adjustments

Meal Assembly Verification

Track and monitor ready-to-eat product assembly for accuracy and portion sizes

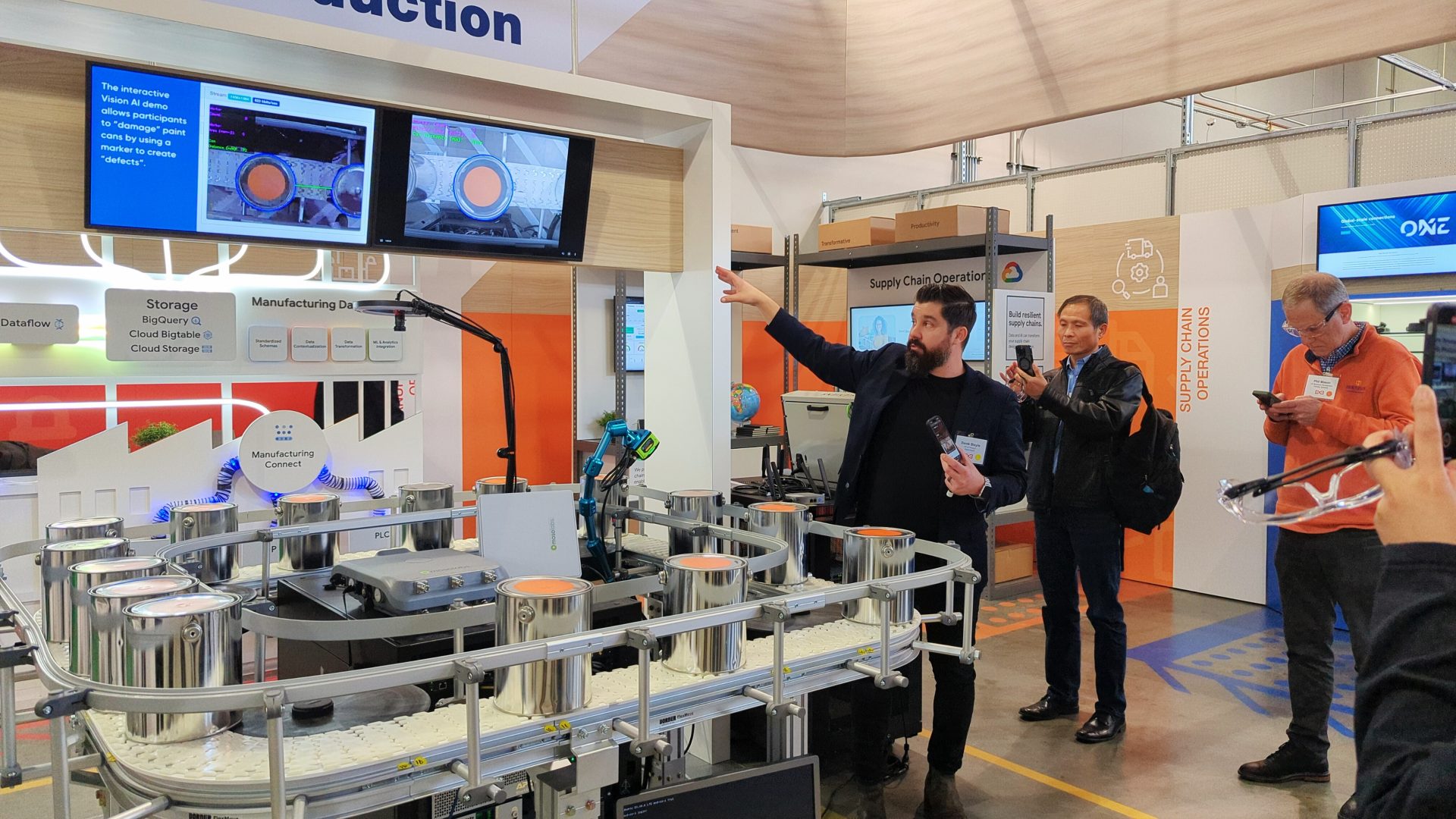

Vision AI in Action:

Clemens Food Group Improves Yield and Quality with Vision AI

Clemens Food Group, a major North American pork processor, uses ClearObject to improve quality and efficiency in its facilities. ClearObject tailored the quality control AI solution to identify pork-specific features and defects, helping butchers extract the most value from each animal. Data collected is then used to manage suppliers based on the quality of product they provide.

(Vision AI) lets plant operators do more with less people, or do things they couldn’t do before. – Stuart Farber, Vice President of IT, Clemens Food Group

Vision AI with ClearVision Benefits

Quality

Vision AI deployed at the edge provides real-time analysis to identify defects and eliminate false-positives, improving both quality and efficiency.

Efficiency

ClearVision reduces downtime and increases throughput with insights into operations. Lines run faster, longer, and with higher accuracy than those monitored by human eyes.

ROI

Reduce waste, cut labor costs, increase throughput, and minimze downtime so QA professionals can focus on solving quality concerns, not on monitoring the lines.

Safety

ClearVision Inference Engine will identify PPE violations, monitor hazardous work areas, and reduce emergency shutdowns to increase worker safety and keep operations running.

Connected

ClearVision integrates seamlessly into your existing systems, and can often use images from existing cameras.

Can’t Wait? Contact Us Today

The ClearObject Team of AI Experts is here to help you get started